A hydraulic press brake is a form of press brake specifically intended to bend metal sheets. It separates itself from mechanical and electric press brakes using hydraulic fluid to deliver force to the press brake turning operation.

Hydraulic power allows it to make varied forms out of different metals precisely.

How Does a Hydraulic Press Brake Differ from Other Press Brakes?

While press brakes have the same goal of bending metal, how they apply force differs significantly between kinds.

The mechanical press brake uses a crank. The electric press brake uses an electric motor. But, the hydraulic press brake of MIHARMLE uses hydraulic pumps to generate pressure. This pressure causes the paired hydraulic cylinders to apply force on the material. This force allows the machine to bend to the right angle. Hydraulics makes operation smoother. It also gives higher control and better bending accuracy. This is especially true for larger, complex parts.

What are the Key Components of a Hydraulic Press Brake?

A hydraulic press brake comprises several vital components that work together to ensure its duty is carried out efficiently. These components include:

• Hydraulic cylinders: These produce pressure for the bending process.

• Machine operator controls: Adjust bending angle, pressure, and other variables.

• Hydraulic fluid: This transmits pressure throughout the hydraulic system.

• Die set: These tools determine the form and radius of bends.

What is the Basic Working Principle of a Hydraulic Press Brake?

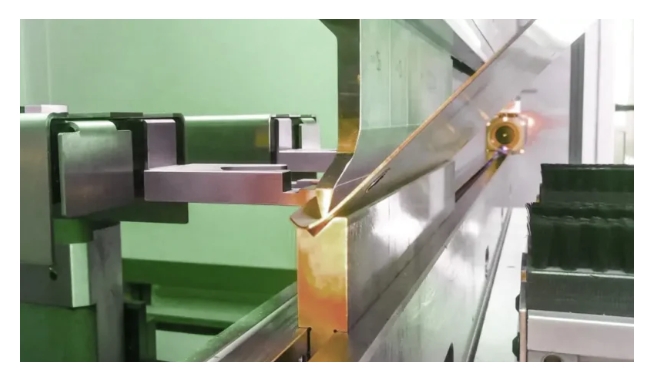

The press brake works on two main principles. It uses the force of hydraulic fluid and the precise control of modern computers. When the machine operator begins bending, hydraulic pumps generate pressure, which propels the hydraulic fluid. This fluid then activates the hydraulic cylinders, which move the ram vertically to exert force on the metal sheet over a die.

The operator can control the ram’s speed, location, and force using CNC machines or computer controls. This control allows for high-accuracy bends.

How Do Hydraulic Forces Allow Bending in Press Brakes?

Hydraulic forces generated by hydraulic fluid pressure enable the bending process in a press brake. The operator controls the hydraulic pressure, which determines the force delivered to the workpiece. This pressure causes the ram to move down, pressing the sheet metal against the die to obtain the desired bend angle.

Why should you invest in a high-performance press brake manufacturer?

If you own a factory, investing in a press brake machine is worth it because of its benefits. Purchasing press brake equipment is a significant investment, but the benefits exceed the price. Here are a few ways a Press Brake might help your manufacturing firm.

Increased Productivity

The main reason you should consider purchasing a Press Brake machine is that it will significantly increase the production of your business. It accelerates and streamlines the production process, reducing the time required to create the same number of parts. This enhanced production rate allows you to get more done in less time and fulfil more orders much faster. It can also result in improved earnings because you can process more orders in less time.

Increased Accuracy

A press brake machine can also improve the accuracy of your production process. It minimizes the possibility of mistakes and guarantees that all parts are manufactured with precision and accuracy. It can simplify reaching higher quality in the items you make. It does so directly, giving you an edge over rival manufacturers.

Improved Safety

When purchasing machinery for a manufacturing firm, safety is an important consideration. The press brake machine is intended to decrease risk and protect the safety of workers. It contains several safety measures, including sensors and automated operations, which assist in avoiding accidents and limit the risk of injury.

Cost Saving

Investing in a Press Brake machine might also help you save money over time. Using automated processes allows you to cut the workforce and time necessary to accomplish orders. It can result in considerable cost savings in the form of lower labour expenses and fewer materials needed.

Versatility

Finally, press brake machines can perform various jobs in the production process. The machine is flexible. It can cut, fold, and bend metal and make parts. This makes it invaluable to any manufacturer.

Investing in a press MIHARMLE brake machine for your factory may bring many benefits. Enter MIHARMLE official website here: https://miharmle-cnc.com/. These include higher production and precision, better safety, and cost savings. If you want to increase the efficiency of your manufacturing processes, investing in Press Brake equipment is well worth considering.